Longxing Coal Fired Heat Transfer Oil Furnace

Basic Info

| Model NO. | YGL |

| Function | Oil Boiler |

| Fuel | Coal-Fired |

| Installation | Assembled Boiler |

| Structure | Oil Tube |

| Media | Organic Heat Transfer Material |

| Water Circulation | Forced Circulation |

| Drum Placement | Vertical Boiler |

| Pressure | Low Pressure |

| Manufacturing Level | B |

| Burning Style | Chamber Combustion Boiler |

| Usage | Industrial |

| Transport Package | Wooden Case |

| Trademark | Longteng |

| Origin | China |

| HS Code | 0841780909 |

| Production Capacity | About 200 PCS/Year |

Product Description

Product Description

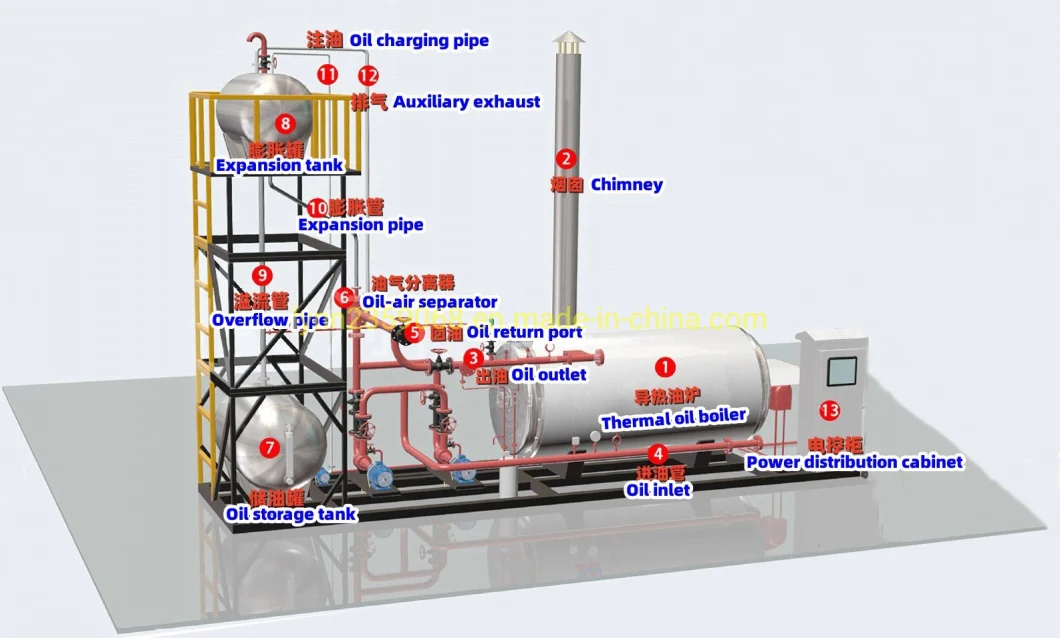

Shandong Longxing Group is a large group manufacturer of heat transfer oil heat carriers and hot water and steam heating boiler equipment. For the past 30 years, our company has been committed to the development, design, and manufacture of a series of oil-fired and gas-fired organic heat carrier furnaces/heat transfer oil furnaces, electric heating heat transfer oil furnaces, oil-fired and gas-fired steam boilers, oil-fired and gas-fired hot water boilers and steam generators, waste heat exchangers and other equipment.The principle of oil/gas-fired heat transfer oil boiler is to use fuel oil or combustible gas as fuel. The balance of the flame volume and heat exchange surface area of the burner makes the outlet flue gas of the exhaust pipe reach the ideal temperature, and the extra thick insulation layer makes the heat dissipation of the boiler reach the minimum. The high-temperature heat transfer oil is used as the heat carrier, and the circulating oil pump is used to force the liquid phase circulation, and the heat energy is delivered to the heat-using equipment, and then returned to reheat. The oil/gas-fired thermal oil boiler manufactured by our company is characterized by compact structure, small size, light weight, simple installation and operation, fast heating, no environmental pollution, etc. The oil/gas-fired heat transfer oil boiler is automatically controlled by the computer, with low pressure (≤0.4MPa) and stable operation, and the thermal efficiency can reach more than 90%.The oil/gas-fired heat-transfer oil boiler is an assembled boiler, which only needs to be connected with the system equipment and pipeline during the boiler installation. The integrated boiler design makes the installation more convenient and fast. This boiler adopts intelligent control to make the boiler operation especially convenient and simple. The controller is displayed on the analog screen and controlled by the central processing unit. It has the functions of automatic ignition and shutdown program control, automatic combustion control, automatic switching and control of circulating pump, automatic fault handling and alarm. Compared with steam heating, the oil/gas-fired heat-transfer oil boiler has the ADVANTAGES of uniform heating, simple operation, safety and environmental protection, energy saving, high temperature control accuracy and low operating pressure. It has been widely used as a heat transfer medium in modern industrial production. It is widely used in petrochemical, textile, printing and dyeing, plastics, food processing, wood processing, asphalt heating, carton production, vegetable dehydration, paint baking, casting sand mold drying, etc. It is a new type of ideal heating equipment.

Characteristics

1. It can obtain higher working temperature under lower operating pressure.2. Stable heating and accurate temperature can be obtained.3. The thermal efficiency can be maintained at the best level under all levels of load.4. The liquid phase transports heat energy. At 300 ºC, the saturated steam pressure of the heat carrier is 70 times lower than that of water.5. It has complete operation control and safety monitoring devices.6. Save electricity, oil, water and consumption, and recover investment in 3-6 months.

Operating Procedures

A. Pre-start inspection 1. Check whether the heating furnace and its surroundings are clean and free of sundries, and whether the furnace body, burner, controller, fire hole, flue (chimney), etc. are normal 2. Reverse the process equipment and flow, check whether the oil level in the expansion tank is above 1/4 - 1/2 level, and whether the thermometer and pressure gauge are normal 3. Connect the power supply of the heating furnace control cabinet, check whether the voltage is normal, and check whether the indicator light and all display instruments are normal 4. Adjust the main pressure reducing valve and secondary pressure reducing valve of the gas to control the pressure to 0.005 MPa.B. Start 1. Start the heat transfer oil circulating pump (one for operation and one for standby, refer to the operating instructions of the water pump), and circulate normally for about 0.5 hour after starting the pump to stabilize the pressure; 2. Press the burner start button to observe whether the furnace flame is burning normally. If not, start the burner again after troubleshooting.C. Shutdown operation 1. Normal shutdown a. Gradually reduce the temperature, shut down the burner and stop burning; b. When the temperature of hot oil drops below 70 ºC, stop the operation of hot oil circulating pump (refer to the operating instructions of water pump); c. Turn off the main power supply and make shift handover records. 2. Emergency shutdownIf the boiler is shut down in an emergency, the burner shall be shut down quickly, and the burner shall be moved away along the hinge axis of the burner to form a natural ventilation state between the furnace and the chimney, so as to dissipate the heat storage in the furnace, so that the heat transfer oil can be cooled naturally and prevent overheating.D. Attention During patrol inspection, pay attention to check whether there is leakage around the heat transfer oil furnace. There should be enough oil fire fighting equipment and electrical fire fighting equipment nearby. Water is not allowed to be used as fire extinguishing agent.

Product Parameters

Notes:(1) Our company can design the equipment according to the user's specific requirements.(2) For the last update of the technology, we will change the technical data without notice, and the correct parameters are subject to the real product.(3) If you are unsure which type to choose, please call us, and our professional sales engineers will recommend one for you.FAQ

Q1. What are your terms of packing?

A: Generally, we pack our goods in plywood cases. If your goods have one container, the goods can be packed without plywood, just be wrapped with the film to load.Q2. What are your terms of payment?

A: T/T 40% as deposit, and 60% before delivery. We'll show you the photos of the products and packages before you pay the balance.Q3. What are your terms of delivery?

A: FOB, CFR, CIF, DDU.Q4. How about your delivery time?

A: Generally, it will take about 30 days after receiving your advance payment for the customized machine. The delivery time depends on the items and your order quantity.Q5. Can you produce it according to the drawing?

A: Yes, we can produce according to your technical drawings. If you don't have the drawing, just tell us your need and our engineer will make the drawing for your reference.Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before deliveryQ7. How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive prices to ensure our customers benefit; 2. We respect every customer as our friend and sincerely do business and make friends with them, no matter where they come from.

Machining Strength